From the roads of the Roman empire to the paper proposals for Google’s Sidewalk labs, from screw gauges to time zones, from urban plans to computational protocols, the genealogy of platforms is replete with grand and mundane schemes. Whether digital or physical, hardware or software, platforms are a general systems type—a standardized foundation, architecture, or arena upon and through which other things are planned and programmed. Platforms perform in similar ways. They combine rigid protocols with flexible adaptation; they consolidate and distribute power; they coordinate supply and demand; they leverage surplus via network effects; they perpetuate early plans while staging the potential for ongoing emergence. Platform systems are also prone to particular pathologies—malfunctions and errors including path dependence, lock-in, and rigid distributions of risk. The case of Fordlandia, the Ford Motor Company’s failed rubber plantation in the Brazilian Amazon, presents one such platform pathology—the slip—which describes the proclivity/propensity of platforms to slide out of sync with the worlds they precipitate. The Fordian slip diagnoses the ways that platforms fail to pivot, demonstrating how peripheral experiments reveal fissures in platform foundations while staging unexpected possibilities as they play out over time.

The Ford Motor Company was the leading choreographer of mass production after the turn of the twentieth century. Ford constructed a series of interdependent platforms that enabled its automobile empire to reach unprecedented global scope and scale. These included the customizable and adaptable core platform base—the chassis—that homogenized and simplified the foundational architecture of a diverse line of Model Ts; the production platform of electrified mass assembly that relied on the careful coordination of standardized parts; the unprecedented economic platform of low prices and high wages; the organizational platform of international factories and dealerships that could coordinate and disseminate materials and motorcars; mass media platforms like Ford-sponsored films and newspapers that accelerated personal desire; and the political platforms that Ford manipulated to support an expanding automotive infrastructure. Ford’s platform of platforms propelled the rapid proliferation of motorcar technologies, orchestrating a virtuous cycle of mass production and consumption that gave rise to a blue-collar middle class in the United States while mobilizing economies worldover. The radical democratization of mass automobility demanded the submission of bodies and brains to the robotic repetitions and frenetic rates of the assembly line.

Fordism describes the paradigm of economic, social, technological, geopolitical, and cultural logics set in motion by Ford’s internal combustion empire.1 Fordism is broadly critiqued for its rigid vertical hierarchy, its extractive emphasis on capital surplus accumulation, and the tight rationalization of production that ultimately led to its demise. A closer review of the Model T’s design, development, and distribution, however, reveals a more hybrid dynamic, a platform logic that enabled Ford’s automotive ecosystem to flourish through top-down prescription and bottom-up adaptation, especially in its early phase. The Model T established steady production capacity through vertical supply, but it also established a horizontal ecosystem of demand that responded to desire and necessity in tandem. Ford’s network of franchises and knock-up factories adopted techniques of modular configuration and customization to circumvent international regulations and outmoded rules. This network was not constructed exclusively through rote command and control; it crafted a process for solidifying protocols while continually modifying and perfecting them. From a “planetary engine” made of interlocking rotating gears to an interchangeable fuel supply, from debt-driven dealerships to standardized parts distributed via Sears Catalog Sales, from Ford Motion Picture Unit movies to policy support for expanded road infrastructures, the Model T leveraged new innovations, shifting the automobile from luxury to utility. Ford’s platform of platforms was in fact not at all fixed or rigid, but made possible through responsive intervention and flexible iteration. In this way, Fordism was, as Francesco Marullo describes, “not Fordist after all.”2

No object of study within the expansive legacy of Fordist platform architectures demonstrates the integrated logic of fixity and flexibility more distinctly than Ford’s River Rouge factory in Dearborn, Michigan, designed by architect Albert Kahn. The River Rouge, which opened in 1917, actualized the Fordist vision of a total assembly machine, a vertically integrated world of global automotive production. As David Gartman writes:

It became clear to Ford and Kahn that mass production required not specialized space for particular purposes but flexible space infinitely expandable and adaptable to any purpose… Kahn built Ford a single-story, steel-framed work shed that was infinitely expandable in all directions, allowing production flows to meander and seek their own paths on the flat landscape. An additional advantage of the site was its ability to connect production flows with the supply flows of raw materials from around the globe through the deep-water port Ford built on the River Rouge.3

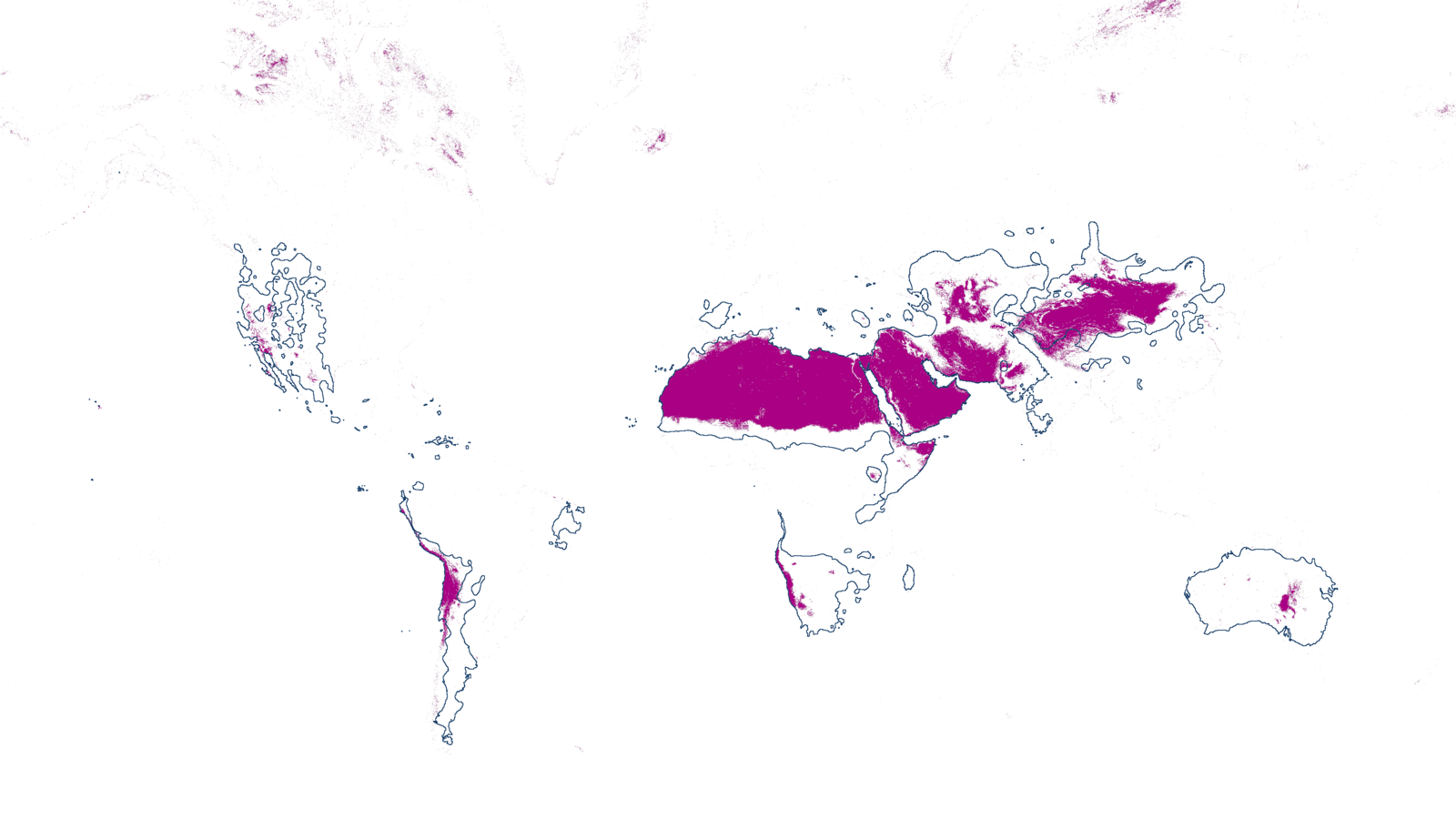

Ford’s factory complex became the epicenter of a choreographed clockwork of glass, leather, metal, steel, and wood, facilitated by Ford-owned shipping and storage infrastructures that stretched across the farthest corners of the Earth. By 1927, when Ford Motors finally shifted focus from the once visionary Model T to the new Model A to keep up with emerging competition, only a single material element remained without steady supply. Rubber was the last missing link in the complete vertical integration of the Fordist production and distribution chain, and Ford sought a plantation platform to close the final loop.

Sawmill and Power House at Boa Vista, later Fordlandia, Brazil, 1932. Credit: Collections of The Henry Ford. Gift of Ford Motor Company.

Plots Without Plans

Throughout the 1910s and 20s, the entrepreneurial quartet of Henry Ford, Thomas Edison, Harvey Firestone, and John Burroughs traversed the newly accessible and rapidly disappearing American wilderness on summer camping trips. Dubbed “the Adventure Tours” by reporters and cinematic documentaries, the trips provided time for light manual labor and leisurely campfire conversation about emerging issues of geopolitical concern, including the Euro-Asiatic monopoly on rubber. Increasing industrial and military demand, alongside frustrations with persistent price fixing in the global market, inspired the four to initiate a rigorous research program into rubber production, with the mission of securing their own source for “mother’s milk.” American-led rubber cultivation, they surmised, would solidify autonomy from British and Dutch production in the Indies and provide an alternative model to the Belgian debacles in the Congo, all while leveraging US government interests in strategic economic alliances outside of Asia and Africa.

Ford’s rubber pursuit was part of a vast matrix of projects led by Ford Motors which hoped to align the potential of industrial agriculture and chemurgic experiment with Ford’s vision of improving the lives of the “great multitudes” worldover.4 Ford tested soybean fuels and developed an entire car out of soybean materials, a speculative prototype that showcased company innovation in exhibitions but never became drivable. Ford attempted to acquire the Muscle Shoals munitions plant in Alabama, with aspirations of converting the explosives factory into a nitrogen fertilizer factory at the center of a new Ford-designed and managed city, but his utopian vision was thwarted by US politicians. By the mid-1920s, Edison’s sprawling estate in Fort Myers, Florida had become the official home of the newly incorporated Botanical Research Labs, a start-up founded by the four Adventure Tour travelers. Edison’s own dream of southern success—the unrequited “ambitions of a poor and uneducated youth and determined to go off to earn his fortune in the fabulous lands of Latin America”—seemed on the precipice of finally coming to fruition.5

On October 13, 1925, a letter from the Russian Agricultural Agency in America addressed to the Ford Motor Company in Dearborn requested a visitation to the Florida test sites and the exchange of rubber seedlings in the spirit of international collaboration with the Soviet cause.6 A handwritten note across the top of the letter suggests it received a formal reply: “Tell them we understood they were to look over the plants in Florida, will see them if they come back.”7 “Their” prospective return—the rubber plants and the Russians—ambiguously alludes both to Ford’s nascent rubber experiments and the growing alliance between the Ford Motor Company and the new Soviet Union. The alliance forged a purchase pact of trucks and tractors and the development of a Ford factory on Soviet soil, advancing the increasingly pressing mission of generating new markets to mitigate against slowing US sales.

In 1927, the Floridian Botanical Research Lab was still waiting on a second round of test seedlings to sprout when Ford purchased a jungle plot in Brazilian Amazonia. The lands were located on an unusually hilly slope some 600 miles south of the port city of Santarem. The property deal was struck in haste, on the first visit by Ford’s Detroit managers to Brazil, without consultation with Ford’s most profitable South American office in São Paulo. The plan to develop a plantation on the site proceeded in spite of many sobering reports by company researchers and the US government, which articulated in no uncertain terms the copious agricultural and cultural impediments to producing substantial quantities of rubber in the region. The reports focused on the myriad difficulties of operating in the territory, including the complexity of managing the indigenous tappers who had worked as independent laborers in the decades prior, during which European barons oversaw the rise and fall of the Brazilian rubber boom.

Accounts of the 1927 trip to survey the Amazonian plots describe an almost mystical momentum that swept over the Dearborn managers on that caipirinha-fueled visit. Paul Villaries, the Brazilian governing official of the region and the owner of the proposed Ford property, was especially keen on the company’s arrival. The rubber economy went bust in 1876, when British explorer Henry Wickham smuggled 70,000 Para rubber seeds out of Brazil. The seeds, categorized as “academic specimens” to avoid regulations against their suspect sourcing, were regrafted at London’s Kensington gardens in preparation for Asian replantation. The contract with Villaries transferred the tappers village of Boa Vista and 2,500,000 acres of land to a new corporate holding, Companhia Industrial de Ford, with promises of not only the most hospitable conditions for rubber cultivation, but also of gold, diamonds, and other treasures, alongside low tax rates on exports from the region. The lands of Fordlandia were officially conferred; a rubber tap and rubber trap.

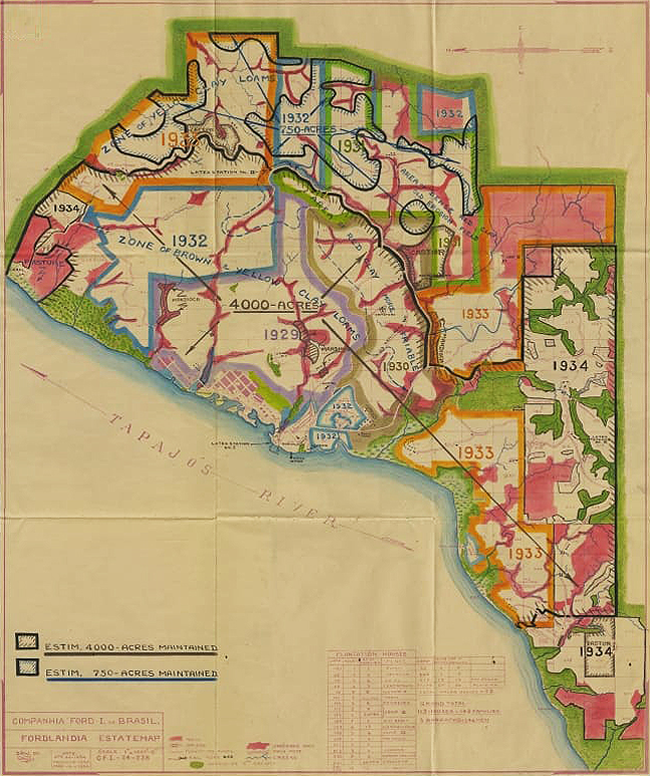

“Companhia Ford do Brasil, Fordlandia Estate Map,” 1936. Credit: Collections of The Henry Ford. Gift of Ford Motor Company.

Decisions taken at the beginning of any platform process have an outsized impact on their trajectories. Platforms build on prior platforms, and early foundations establish parameters for further development. This phenomenon is known as path dependence, or persistence, and the debacle that subsequently ensued in Fordlandia can be in large part traced to preliminary missteps that had outsized impact on everything that followed. In the spring of 1928, soon after the official purchase of the plot, the Norwegian sea captain Einard Oxholm led the first expedition from Dearborn, Michigan to the new Amazonian settlement, overseeing the long journey of a large steamer and a barge in tow. The haul housed “everything that spells civilization to the white man,” including tractors, prefabricated buildings and houses, a sawmill, food, hospital equipment, a powerhouse, ice-making machinery, and railroad equipment.8 From the outset, nothing proceeded as planned. The steamer and barge got stuck at the mouth of the Tapajos River. The captain rejected local offers to ford the low river waters during the dry season, which left the ships waylaid for almost a year, at the substantial cost of both resources and local respect.

Unlike in Detroit and other global sites, where Fordist production was platformed through iteration on existing conditions, in Fordlandia the plantation was imagined to be instantiated almost from scratch. In classic colonial form, Captain Oxholm, who had no agricultural experience to his name, was appointed plantation manager upon arrival to Boa Vista via a telegram from Ford headquarters in Detroit. His first, self-declared order of business was to burn Boa Vista and the surrounding forest. This act of tabula rasa not only destroyed the potential for local relations, but also depleted the topsoil’s nutrients and obliterated the forest’s over and understories, a jungle ecology which protected the existing Hevea rubber trees. After the fires subsided, the new village of Fordlandia was erected with veritable speed. Ford workers paved a main road with imported tractors, constructed a central company office, erected a water tower, installed a radio station, and established a port along the river. Two factory spaces with giant glass windows went up, overlooking the river from high on the hill. The company mapped the lands into a grid for tracking agricultural progress acre by acre, plot by plot. Posters recruiting rubber tappers were circulated up and down the Tapajos River, offering promises of housing and Western luxuries alongside an unparalleled high wage of 35 cents a day—copying the economic platform logic that had ensured a steady labor supply in Detroit.

At first, tappers arrived in droves. But the rote overprescription of labor protocols from the Fordist factory, so successful in Detroit, prohibited intelligent adaptation to this new location. Social control took precedence over successful capital production. The previous labor regime had paid workers per harvest bucket, and tappers worked in the mornings and evenings, efficiently avoiding the peak jungle sun. The Ford managers insisted on applying the American formula of continuous eight-hour workdays under the sweltering Amazonian heat, pushing workers to exhaustion. The once uneven and interspersed forest of Hevea rubber trees was replaced with monocultural rows, which accelerated the transmission of disease. The prefab, suburban style housing imported from Michigan let in bugs and heat, proving far inferior to the thatched-roof architecture perfected over the years by indigenous tappers. The American managers prescribed a missionary spirit, insisting the tapper communities participate in English sing-a-longs, square dancing, and the cultivation of small garden plots. Hammocks were prohibited, and fainá, the local cornmeal staple, was banished from the Fordlandia workers’ cafeteria. Alcohol was banned from the company town, a rule that the company managers visibly ignored. In response, the tappers established their own “island of innocence” on an islet across the river, a jurisdiction for revelry and pleasure just a short boat ride away.

The economic and social protocols in Fordlandia, which ignored the virtuous cycle of production and consumption so critical to Ford’s platform growth in Dearborn, eventually contributed to the plantation’s demise. In Fordlandia, high pay proved to be an inadequate incentive to sustain a grueling and inefficient work regime, and there was no sensible outlet for the expenditure of social energy or accumulated capital. The single company store in Fordlandia suffered from continuous vendor turnover, and the original wares shipped in from North America, including bizarre provisions such as high heeled shoes, were of no relevance to the Amazonian tappers. As a result, tappers regularly abandoned the plantation after a few weeks of work to spend their wages elsewhere. The capital system of debt and accumulation, which accelerated the demand for personal car ownership in the US, was irrelevant to a society whose mobility depended on rivers rather than roads. Fordlandia’s middle managers misunderstood tapper resistance to their paternalistic regulations, casting them as irrational savages, rather than recognizing their far more rational and efficient calculations of energy and economy in the jungle context.9

The archive of company communications from the plantation’s head office demonstrates an impressive degree of managerial control and composure. Copious records of transactions, records, and plans catalog a clear path to successful rubber production and company operations. The situation on the ground, however, proved to be substantially different than the pictures presented in written reports. In 1933, after years of mounting discontent, plantation workers revolted, prompted by the introduction of American cafeteria-style self-service and hamburgers to the Fordlandia workers’ cafe. The 2,500 workers living at the plantation, joined by 7,500 kin, set fire to the budding trees, smashed the clocks, burned the administrative buildings, and hijacked the Marconian radio network that enabled communication between the Dearborn headquarters and its Amazonian satellite. The American managers were rescued by a private plane dispatched from a Pan-Am executive’s nearby compound. The plantation revolt sent ripples of resistance across the villages along the river highway, surrounding the Ford property with rebellion.

Car Stuck in the Mud at Fordlandia, circa 1940. Credit: Collections of The Henry Ford. Gift of Ford Motor Company.

The riots created a dramatic setback, but they did not halt Ford’s plantation efforts in Brazil. Like any platform, the initial investment in Fordlandia was high risk, and patiently anticipated extensive returns. In the aftermath of the revolts, the company declared Fordlandia a research station, and a new plantation city, Belterra, was established nearby upstream. In Belterra, many of the same mistakes played out, this time as farce. A new cycle of managers was imported from Detroit, relieving the previous cohort from mental and physical afflictions, while precluding the transfer of ecological, sociological, and operational insights. Each new crop of managers repeated the very same process of razing the grounds and planting monocultural rows, which yielded the same ecological pathologies of blight, bugs, and disease, prohibiting the growth of rubber trees on any sufficient scale. In Belterra, however, some crucial adjustments to Fordlandia’s initial attempts at social rationalization successfully recalibrated the plantation operation. Gone were the paternalistic singing and gardens intended for social conversion. In their stead were the physical infrastructures necessary for any modern urban platform—fire hydrants, electric lines, tidy roads, water networks, hospitals, and schools. This phase of Fordist management of the city of Belterra remains celebrated today, an aspirational model of social infrastructure that persists in popular memory, without a governance or economic platform to support it.

Regardless of the advances made in Belterra, Ford’s Brazilian rubber plantations never produced sufficient supply. The Russian discovery of neoprene in 1932 ultimately led to the ascendancy of synthetic rubber in the post-World-War-II era. In 1946, after the death of his grandfather, Henry Ford II consolidated Ford company holdings, abandoning international experiments that undermined the company bottom line. The Ford plots were sold back to the Brazilian state of Para at a substantial loss, an equivalent of approximately 250 million USD today. Fordlandia’s failure might be considered a platform “stragedy”—the tragedy of strategy, a plan that fails to adjust and adapt to its context and conditions. The rote application of Fordist protocols in Fordlandia took precedence over the adoption of the more fundamental platform principles so successful in Detroit, including technological iteration, global integration, individual incentives, and mobile infrastructures. Social prescriptions focused on building a closed microcosm, preventing Fordlandia’s participation in the global production platform that Ford had so successfully developed elsewhere. The debacles in Fordlandia foreshadowed the ruins of Detroit, a far more profound slip in platform adaptation that would characterize the Fordist future to come.

Slope and Scale

The Freudian slip, known in psychoanalysis formally as parapraxis, diagnoses a pathology of undisclosed personal motive revealed in language or gesture or routine mistake. Freud’s famous essay on the subject concludes by describing it as occurring beyond simple accidents, saying that it can also be applied to “the more important errors of judgment, as evinced by people in life and science.”10 The Fordian slip shifts the diagnostic register of the slip from personal psychic motives to the dynamics of momentum that underpin platform systems themselves. The Fordian slip describes the pathological tendency of platforms to entrench primary decisions and fixed protocols, ones that at a pivotal moment supersede flexible principles, preventing platforms from adapting to the rapid changes in contexts that platforms themselves create. The Fordian slip presents a prototypical platform pathology—the drive to plan a closed system based on the outcomes of platform pervasiveness rather than continuing to leverage the open principles of incorporation, coordination, and modification that enabled their growth in the first place. By focusing on imposition rather than iteration, on the small company town rather than the expansive integration of emergent infrastructure and information, Fordlandia’s platform collapsed from within.

In its most literal sense, a slip is a loss of steady footing, an abrupt and jarring impact of shifting ground, revealing a failed anticipation of the ground’s expected position. Fordlandia’s geographic terrain was an insurmountable platform at the outset: a sloped and uneven foundation inhospitable to agricultural cultivation. Perhaps nowhere does this topography prove more apparent than the Fordlandia villa perched high on a hill, which was built for but never visited by Henry Ford himself, whose unfulfilled promise to visit remains a persistent local rationale for Fordlandia’s ultimate demise. Ford’s crumbling house now overlooks the twin decrepit processing plants, a large central church whose bell continues to chime, the Fordlandia school, and the worker houses squatting beside the river that were resurrected after Ford’s abandonment. A visit to Fordlandia today immediately reveals what maps and plans don’t readily make apparent: the same steep hills that ultimately prevented monocultural productivity provided clear observation of the river approach, ensuring protection from infiltrators and surveyors. The slip is duplicitous regarding motive and momentum. Focus too much on the scope, and miss what’s emerging on the ground. Focus too much on the ground, and miss what’s emerging across scales.

The slip is a falling or sliding; something presumed to be predictable is revealed to be off course, a submission to a larger movement underway. One can also slip in or away; an undetected entrance or escape—an unremarkable or imperceptible transition between one thing to another. In any case, the slip demonstrates a change of circumstance only recognizable after the fact. In this sense, the slip is a platform pathology, but it also often presents a potential opportunity. Because platforms always enter real contexts en medias res (in the middle of things), some of the momentum that propels a platform operation might not become apparent until far after the platform’s initial circumstances and conditions fade away. A platform that slips into existence activates an opening that emerges from shifting conditions, maneuvering into being without acknowledgement or announcement. In Fordlandia, locking-in foregone conclusions at the cost of contextual observations perpetuated larger system malfunctions of the rubber operations and its social milieu. But platforms survive by adapting malfunctions towards unexpected outcomes. Platforms shift ends and means.11 They are not wholly prescriptive from the outset, but incorporate emergent developments into their protocols as they go, drawing upon successes and accidents to transform fixed rules based on the worlds they precipitate. If a platform doesn’t slip into existing conditions at the outset, it’s far more likely that it will eventually slip up.

The stories typically told about Fordlandia’s abandonment, by company officials and academics alike—from its failed rubber production to its eventual submission to the forces of jungle wilderness—very well might continue to perpetuate and obfuscate other platform operations, ones that, like the extensive tunnels that run beneath the city, remain hidden to formal history. A close review of the Fordlandia archives reveals that the plantation platform originally built in pursuit of one purpose—to harvest rubber—was co-opted for lumber while waiting for newly planted trees to grow. Discussions with residents from the period suggest that prolific lumber proceeds shifted the failing quest for rubber into a decoy for other covert operations, including the import and export of materials not fully sanctioned by the original contract. An elderly woman who worked at Fordlandia’s rubber processing plant recounted the story of a log that rolled off of a ship loading platform and split open, revealing a cascade of gold and diamonds within the center hollow where rubber once bled.12 It’s possible that Fordlandia appears as a debacle today because it continues to disguise a fraudulent pivot from the original plan: a smuggling platform at its core.

The entire Fordlandia episode, and the Fordian slip at the periphery of Ford’s pervasive platform of platforms, demonstrates the ways that platform pathologies in the long run might themselves be leveraged as antidotes to their own proclivities, extending their pharmacological nature as both poison and cure. Through recombinatorial logics and open positioning, through relay and delay, platform detritus can, with ample insight, be converted into deeply pragmatic and anti-prescriptive programs, ones that combine repeatable platform logics with the deeper rationalities that emerge from below and beyond. Almost eighty years after its abandonment, Fordlandia today has been almost fully resurrected; a village built from the remains of a prior failure. Village inhabitants now strive for development, interconnection, and independence, leveraging the Ford legacy and global notoriety to advocate for autonomy from Santarem, the closest major municipality, to plan and govern its own affairs.

Today, the former Fordlandia factories have been reclaimed as greenhouses and sites for machine restoration, places to rehabilitate an array of resources leftover from the times of Ford. The large former Ford weighing station on the river is poised to become a source for hydropower generation, a viable alternative to the Dutch hydroelectric dams along the Tapajos River that fail to power the villages adjacent to their source. Fordlandia’s youth, more globally connected than most Amazonian youth, are actively using social media platforms to advocate for the jungle city as a base site for collective action towards Amazon-wide forest rehabilitation. Reorienting from isolation to integration, the plantation platform that revealed the Fordian slip as a platform pathology might ultimately become a platform for proactive planetary cultivation, proliferation, and reforestation, one especially poised to protect and preserve the jungle that Ford first destroyed.

Jessop, Bob. Fordism and post- Fordism: A critical reformulation. Lancaster Regionalism Group, 1991.

Marullo, Francesco. “Architecture and Revolution: The Typical Plan as Index of Generic.” The City as a Project, edited by Pier Vittorio Aureli, Ruby Press, 2013, p. 228.

Gartman, David. From Autos to Architecture: Fordism and Architectural Aesthetics in the Twentieth Century. Princeton Architectural Press, 2010.

Ford, Henry. My Life and Work. New Delhi: General Press, 2018.

De Solla Price, Derek J. Science Since Babylon. United States: Yale University Press, 1975.

The Russian Agricultural Agency brokered organizational connections between emerging networks of Soviet agronomists and institutions and American agricultural colleges, companies, and institutes.

Accession #6, Edsel B. Ford office papers, Box 24. Henry Ford – Rubber Plantation. Benson Ford Research Center, The Henry Ford.

Grandin, Greg. Fordlandia: The Rise and Fall of Henry Ford’s Forgotten Jungle City. New York: Henry Holt and Company, 2010.

Sahlins, Marshall. Stone Age Economics. London: Routledge Classics, 2017.

Freud, Sigmund. Pathologies of Everyday Life. New York: MacMillan Company, 1914.

Singleton, Benedict. “The Long Con.” In When Site Lost the Plot. Edited by Robin Mackay, 105-120. United Kingdom: Urbanomic Media Ltd., 2015.

Radio Espacio Estacion, Transmissao Fordlandia, Radioee.net, online broadcast, September 17, 2017.

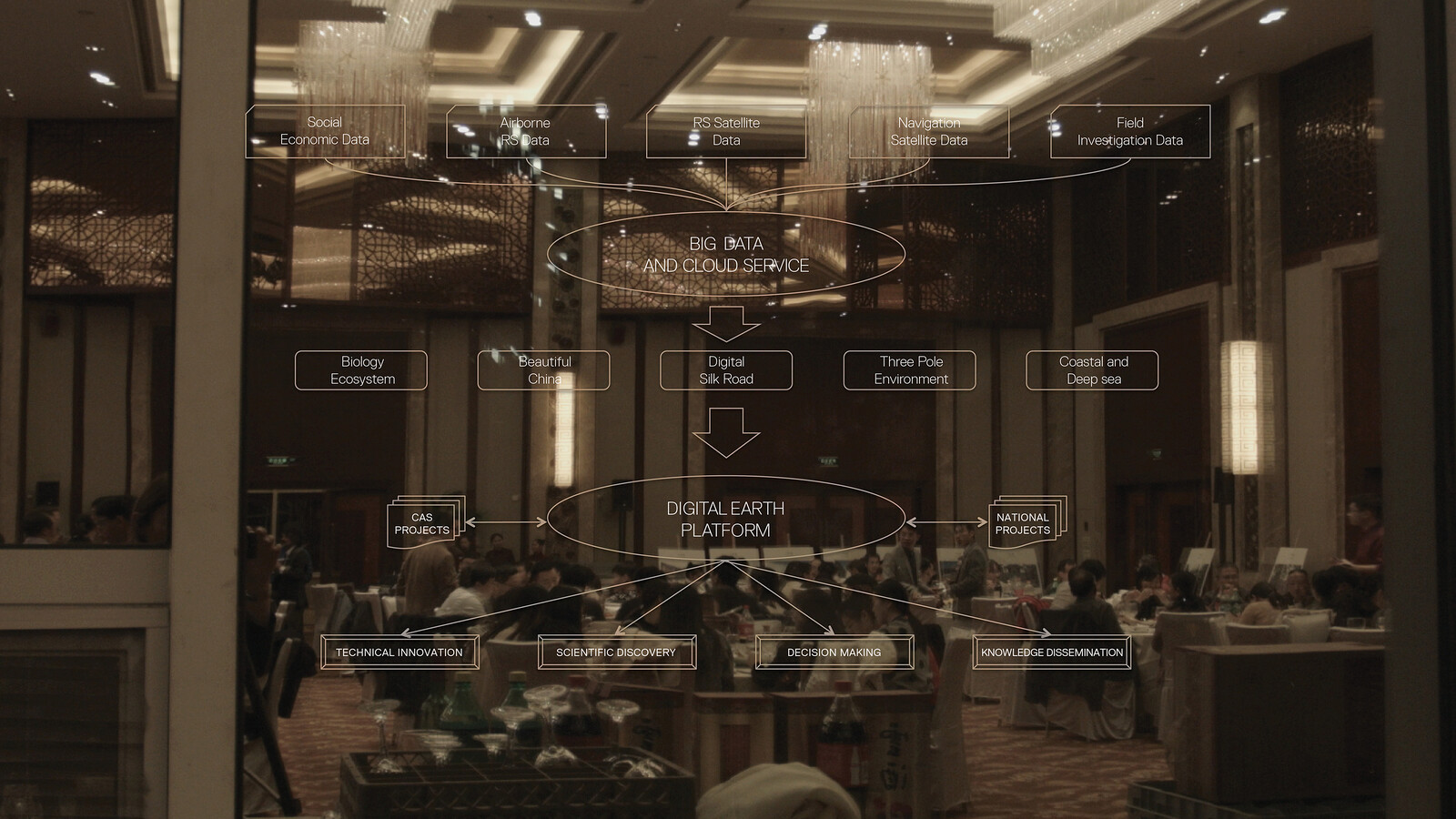

New Silk Roads is a project by e-flux Architecture in collaboration with the Critical Media Lab at the Basel Academy of Art and Design FHNW and Noema Magazine (2024), and Aformal Academy with the support of Design Trust and Digital Earth (2020).