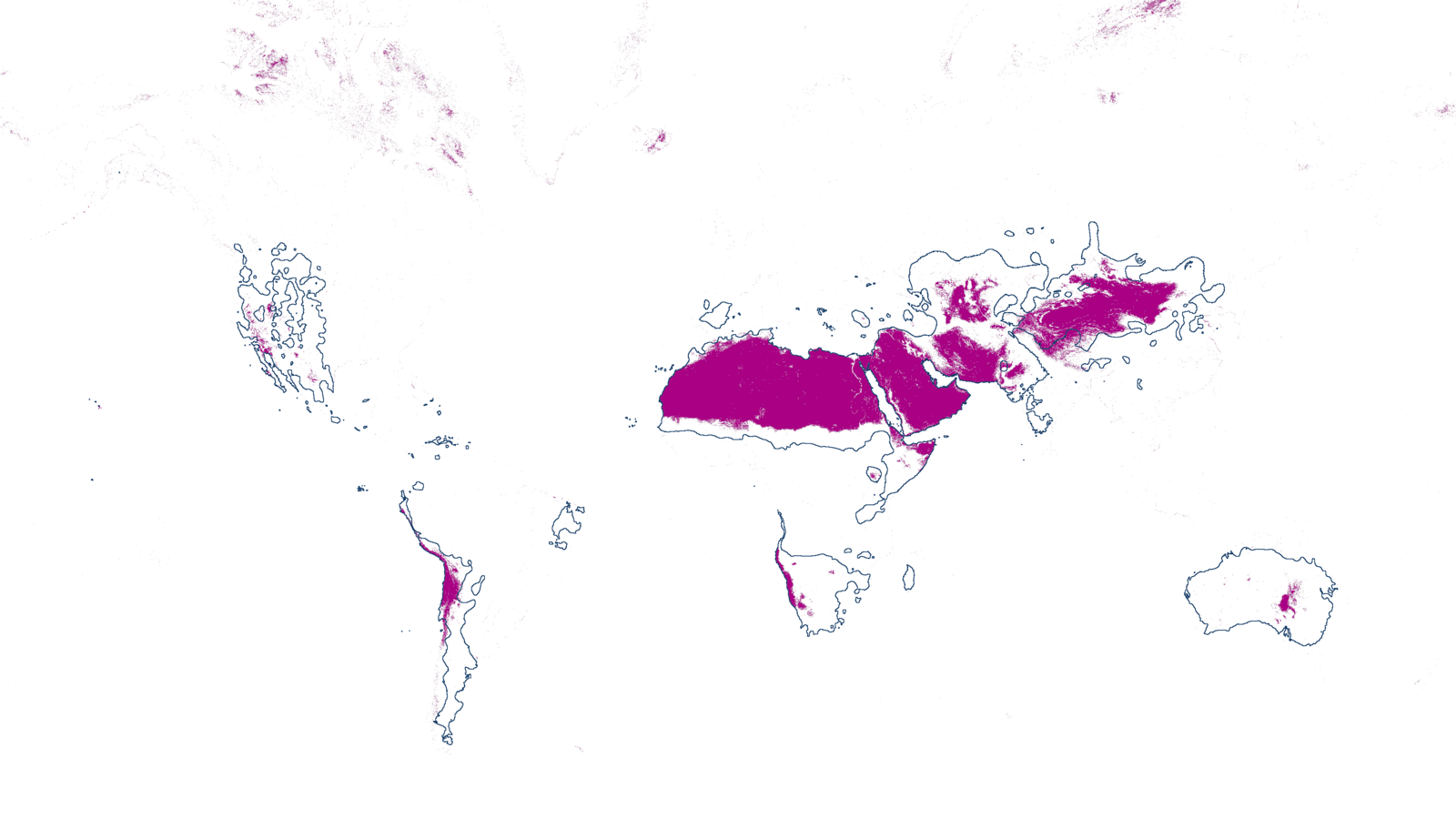

Spaces of global production are formed by a diverse set of spatial figures that result from and support a global division of labor.1 Spaces of global production include multinational manufacturing networks, industrial agglomerations, plantations, logistics corridors, and special economic zones. They are often created on the outskirts of cities, walled by physical fences, and rife with access restrictions. Keller Easterling describes the governance of these spaces as “extrastatecraft,” created by a mix of international economic instruments and legal exemptions that are “sometimes mixed together with domestic civil laws, sometimes manipulated by business to create international law, and sometimes adopted by the nation in its entirety.”2

The power of global capital can be traced to its ability to change or create laws, often tailored to the “special” label these spaces bear.3 However, these laws are still shaped by actual governments, and these spaces still require banal necessities like building permits, water, and an electricity supply, all of which ensure their connection to existing, tangible systems inhabited by real people. Global production spaces are thus special and mundane at the same time. However, these spaces are often obscured.4 Consequently, global factories pose a challenge for anthropological, ethnographic, or social studies that seek to unveil the mechanisms behind networked infrastructure.

Kuklen Industrial Park is one part of the largest ongoing investment project in Bulgaria, the Trakia Economic Zone (TEZ). Gaining access to the site beyond a guided walk requires substantial time, creativity, and commitment. As a result, over the past four years, I have taken on various roles within the industrial park: conducting workshops with real estate managers; training as an assembly line worker; working in the local municipality; and spending countless hours in the workers’ break room over coffee and cigarettes. The following account presents four views of Kuklen Industrial Park from distinct perspectives, creating a multilayered description of a global production space.

I: The Developer’s Dreams of Resilience and Profit

The origin of the Trakia Economic Zone (TEZ) can be traced back to 1999, when the construction company Sienit constructed a cherry processing plant for the chocolate company Ferrero on former agricultural land near the city of Plovdiv, the second-largest city in Bulgaria.5 Sienit then saw further opportunity to generate profit by attracting more international manufacturing firms interested in outsourcing their production to Eastern Europe. They initially focused on purchasing agricultural land, which they would re-zone for industrial use and sell to investors, along with their construction services. Based in Plovdiv, Sienit purchased land and consolidated it into three industrial parks: Maritza, Rakovski, and Kuklen. Since 1999, the project has grown from a small-scale initiative into one of Bulgaria’s most significant economic operations, hosting more than 30,000 workers in 130 production facilities and generating total investments of more than one billion euros.6

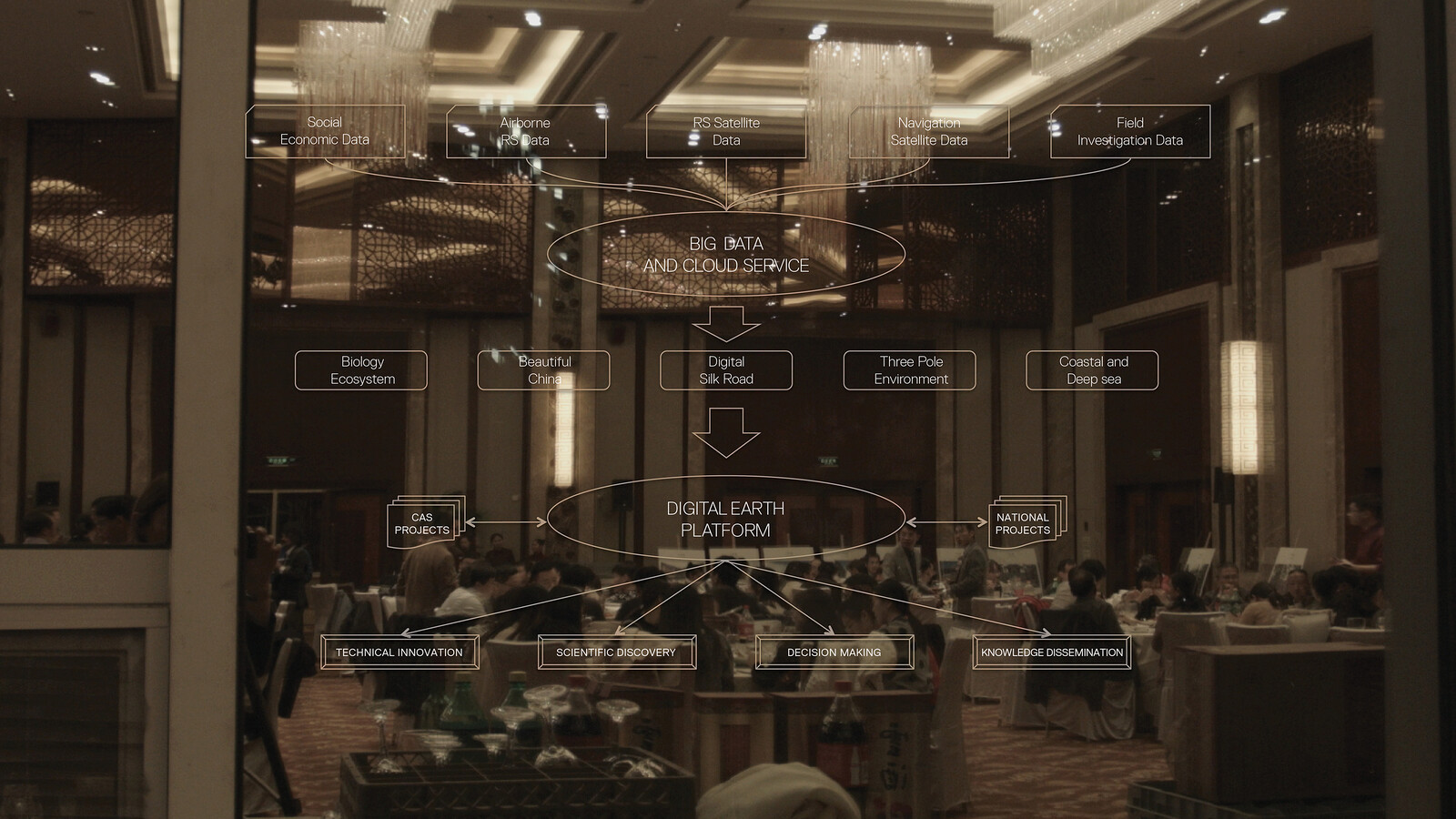

Over the past few years, the TEZ has saturated its capacity to accumulate global capital interest. Most of the available land around Plovdiv is already developed, so the company can’t offer new lots for industrial development. This has led to a transformation in the management practices of the TEZ, which is now not only focused on attracting new investments but also on starting its own industrial ventures.7 Furthermore, since global institutions such as the World Bank, the European Central Bank, and the European Union began redirecting funds to sustainable projects in 2019, Sienit has rethought its business model of buying, selling, and developing land, and launched a strategy for a carbon-neutral industrial park. Rather than a project for a new park, however, the strategy summarizes and rebrands the existing efforts of the TEZ as compliant with sustainable institutional policies, such as those described by the Sustainable Development Goals of the UN, the EU Green Deal, and the New European Bauhaus.

Although framed in language such as “sustainable,” “social,” and “responsible,” Sienit’s core operation is not changing. Their main purpose is still to trade land and offer construction services. Currently, as a private investor, Sienit does not have access to the same financial mechanisms as public entities, which receive better conditions for loans (like no interest and longer lending periods). By framing their operation as in the “national interest” and in collaboration with government and policy makers, they are attempting to be seen, if not treated, as a public entity. This is a clear example of “greenwashing,” but the company has dedicated significant effort to seeking out expertise on how to implement their new sustainable agendas. However, there is little practical knowledge within global infrastructure spaces and transnational entities such as the EU, UN, etc. on how to support the environmental transition that is desired by European politicians.

II: The Birth of Kuklen’s Global Industry

Kuklen Industrial Park is the newest park in the TEZ, and was jointly developed by Sienit, the Municipality of Kuklen, and the lead and zinc processing plant KCM in 2006. The park is located on former agricultural fields in the Kuklen Municipality, which is one of the smallest and newest municipalities in Bulgaria, with 6,256 inhabitants spread over 148 square kilometers. Kuklen hosts not only the growing Kuklen Industrial Park, but also KCM, which is one of the largest factories in the country. The lead and zinc processing plant was built in the 1960s as part of an industrialization plan by the Communist Party to create the missing working class in Bulgaria. It exported 80% of the lead and zinc it produced, and thus occupied a crucial position in the Bulgarian economy. This is why the plant was one of the few communist factories to survive the de-industrialization and privatization that followed the fall of the communist regime in 1989.8 The economic importance of the factory is what ultimately made it possible for the villages around it to form an independent municipality, Kuklen, in 2001.

Intensive metal processing at KCM during Soviet times led to the extensive contamination of soil, air, and water in the region.9 As a result, municipal-owned agricultural lands are unsuitable for most agricultural activities. That land then became the Kuklen Industrial Zone in 2003, when multinational companies began flocking to Bulgaria to take advantage of land and labor along the new European frontier. KCM and Sienit Holding Group partnered in 2001 to purchase the land and sell it to foreign investors. In 2005, the first German-owned factory for automotive parts, Mecalit, opened its doors in Kuklen. Currently, the zone houses seven factories owned by German, Turkish, Belgian, and Bulgarian companies. In 2013, the park became part of Sienit’s TEZ project, which united the industrial parks of Maritza, Rakovski, and Kuklen under one overarching brand.

While Kuklen Industrial Park was framed as a public-private partnership between the municipality, KCM, and Sienit, the role of the municipality has been reduced to selling the land and issuing building permits. As part of my research, I worked with the municipality on developing their strategic plan for integrated regional development, a document required by the Ministry of Regional Development. When I asked about the significance of the global industrial zone to the region of Kuklen, the municipality’s answer was straightforward: none. Only a handful of people from Kuklen work in the zone. Most of the workers live in the bigger cities around it. The municipality receives waste management tax and some extra state funding to build new roads to the factories, but any further strategic cooperation or development is lacking.

The industrial zone of Kuklen is thus a cross-territorial project with significance far beyond the small municipality, drawing people, products, and machines from all over the world. But all those elements are highly mobile, and, just as people move freely, so do factories.10 As a result, the factories are nonspecific to the activities that might take place within them and are instead designed to accommodate a wide range of needs. Factories are primarily prefabricated rectangular sheds, made of grids of concrete columns that are covered with cladded aluminum sandwich facades and monotonous window openings.11 This separation of production from real estate is a relatively new development at Kuklen.

Contrary to the popular political narrative that “automotive production is a long-term investment,” the silent takeover and fragmentation of machines, products, buildings, and people reveals that automated landscapes are rather easy to dismantle. Yet while global production can easily move to new frontiers more suitable for the needs of cheap production, the land always remains. This shift of perspective, from mobile to grounded, could have implications for how governments and municipalities deal with the planning and design of industrial parks, positioning land not only as a commodity, but also as a living milieu and common good.

III: The Myth of Automation

There are around 2,000 workers in the seven factories of Kuklen Industrial Park. Organized within steel boxes and among huge machines, the area devoted to automotive production is bursting with human life. Despite all of the mechanization efforts that have taken place, people still play a crucial role in the implementation, operation, and general success of manufacturing.12 Atanas (Nasko) Diskelev is one of those workers, a young engineer whose story is representative of a whole generation of Bulgarians. Originally from a small village in the Balkan Mountains, Nasko graduated from university as an agricultural engineer in Plovdiv. However, since there weren’t many opportunities in agricultural production, Nasko returned to his village to work in a Swedish factory making bearings. After three years, he moved to his mother’s house in Asenovgrad and started working for Odelo, a Turkish factory for automotive rear lights in Kuklen Industrial Park, which is where we met. Although formally trained, he started his employment on the assembly line, a common way of learning the system of production. He then rose through the ranks, becoming the team leader of an assembly line and ultimately a technical engineer responsible for operating the machines.

In 2021, I was trained by Nasko to become an assembly worker myself, and spent significant time with him. Even though everything in the factory seems highly structured and organized, it is not easy for a newcomer to understand everyone’s tasks and responsibilities. During my training, a new model of car lights was introduced, which caused a lot of chaos and necessitated a lot of machine adjustments, technical tests, and production stops. I was told that this is common, and that it takes an average of a year for the production lines of new models to run smoothly. This meant Nasko would often stay after hours and come in on weekends to fix machines. What was striking was that, often, he would do this on a voluntary basis. He even seemed to enjoy it, whether because he had developed a special relationship with the machines or because he simply liked the challenge of fixing things.

And things certainly needed to be fixed. Machines are unreliable and often break, even in the highly automated sector of automotive production. Therefore, Nasko’s expertise is of immense value to the factory. It’s no surprise that many factories try to retain trained workers, especially since Bulgaria is the fastest-shrinking country in the world and labor is scarce.13 In the Kuklen Industrial Park, companies have taken extreme measures, such as an informal agreement between the first three companies in the park to not steal each other’s workers. This agreement, however, was discontinued as new companies relocated to the industrial park. Still, as a result, Nasko was initially unable to easily switch employment or renegotiate his contract. However, in 2023, he got a job at a new bicycle manufacturer in the park, right next to the Odelo Factory. In 2024, Nasko left Kuklen Industrial Park for new employment. Retention challenges explain the rising number of foreign workers who fill the factory halls. Recently, incoming workers have tended to come from Ukraine. However, negotiations with countries as far away as Uzbekistan and Kazakhstan are currently underway. With the demographic crisis in Bulgaria, a huge foreign labor influx is seen as the only way to continue developing global production, affirming the labor dependency that Western manufacturing has on its Eastern frontiers.

IV: Encounters With a Shepherd

Often, global infrastructure spaces such as the TEZ are depicted as a form of “urbanization” that transforms empty land through development, dedicating it to the best-value use. However, land is never truly empty: it is simply filled with non-human life.14 Most of the wildlife found in Kuklen Industrial Park bears resemblance to similarly abandoned agricultural sites throughout the country, revealing traces of past use. In the 1910s, not only did Bulgaria have a thriving agricultural sector, but it was also the European country with the most sheep per capita (two per person).15 One hundred years later, that number has declined by more than ten times. The region of Kuklen is, however, still a locus of sheep farming, which often takes place today in former industrial spaces. The former military barracks near Kuklen Industrial Park houses a small flock of sheep managed by a shepherd, Georgi, and his two sons.

I met Georgi when I began following the sheep that roamed around the factories. I was surprised to find he was one of the most difficult people to engage with in my research. While factory owners, managers, and administrative representatives eagerly responded to my requests with the hope of accessing my Swiss institutional knowledge and connections, Georgi perceived me as part of a privileged corporate culture. He assumed that anyone working with industrial developments—which I had been—would only want to throw him out of the area. While this is not necessarily true (most of the firms are not even aware that there is a sheep farm next to their factories), industrial development has not been supportive of his livestock farming. In the four years since I started working there, there has been extensive building activity. A large truck parking lot, to cater to the many factories that have been built right next to Georgi’s farm, has cut into the pastures that his sheep used to roam. It is much harder today than it was even two years ago to see a sheep from the places where workers take their breaks, which seemingly confirms Georgi’s theory that modern factories and traditional agriculture cannot coexist. However, if this is true, it is not because of a conscious strategy, but rather a result of the lack of awareness and care for practices that predate the industrial park.

Multispecies map of Kuklen Industrial Park. Drawing by Alicja Prusinska.

Social space intervention in Willi Elbe Factory. by Marko Mrcarica and Pascal Bertschi. Photo: Mihail Novakov.

Social space intervention in Ulo Factory by NEWROPE Chair. Source: Mihail Novakov.

Multispecies map of Kuklen Industrial Park. Drawing by Alicja Prusinska.

To change this perspective, I conducted a series of actions with the Municipality of Kuklen and the NEWROPE Chair of Architecture and Urban Transformation at ETH Zürich, aiming to generate interest in the livestock tradition in Kuklen Industrial Park. These activities included biodiversity mapping, conducting soil tests, providing guided visits to Georgi’s farm for various public and private actors, and opening the factory fences so sheep could pass through its open spaces. Students followed the sheep herd as it moved through factory fences and logistical traffic. Observing the itinerary of the herd demonstrated how the livestock, similar to many non-domesticated species, adapted to the environment, such as by being aware of lorry sounds and warning each other about danger. In a workshop with four factory managers and the mayor of Kuklen, we discussed how to adapt the current urban design of Kuklen Industrial Park to foster and include other economic practices, such as pastoralism.

Interventions such as these were not intended to be universal solutions for factory floors, but rather ways to form meaningful relationships between scales, people, and networks of the contemporary factory. Such design actions were ultimately a way to disrupt our idea of infrastructure as a dominant and disruptive physical structure that connects goods and flows, and instead to investigate more just models for infrastructure as an open and dynamic system, one that fosters connections of care on the ground. Rather than providing concrete solutions, these actions served as a framework to develop spaces for dialogue and critical propositions about the possible coexistence of modernity and tradition.

Stefan Ouma et al., “Spaces of Global Production,” 1–13, in International Encyclopedia of Geography: People, the Earth, Environment and Technology, ed. Douglas Richardson et al. (Chichester: Wiley, 2023); N. M. Coe, P. Dicken, and M. Hess. “Global Production Networks: Realizing the Potential,” Journal of Economic Geography 8, no. 3 (February 29, 2008): 271–95.

Keller Easterling, Extrastatecraft: The Power of Infrastructure Space (New York: Verso, 2016).

Jonathan Bach, “Modernity and the Urban Imagination in Economic Zones,” Theory, Culture & Society 28, no. 5 (September 1, 2011): 98–122.

This obscurity is somewhat understandable, given concerns about industrial espionage and safety issues. Merve Bedir et al., eds., Automated Landscapes (Rotterdam: Nieuwe Instituut, 2023).

Plamen Panchev, CEO of Sienit, has stated in numerous media interviews that the process of building the Ferrero factory was an eye-opening experience regarding the possibilities of industrial development, how global production works, and how Plovdiv can be a player in the European landscape of industries. “Plovdiv’s Road to the Industrial Center of Bulgaria,” ECONOMIX.BG (blog), March 16, 2017, ➝.

This is based on data provided by TEZ management. However, TEZ doesn’t gather systematic data on the number of workers but rather relies on data provided by Industry Watch, an economic analyst in Plovdiv. Industry Watch itself stated that they do not gather data specifically for the TEZ but for the whole region. Therefore, the exact number is unclear.

“Haskovo is now part of Trakia Economic Zone,” Manager BG News, March 23, 2017, ➝.

Hara Yochi, “Industrial Pollution Improvement Project in Plovdiv, Bulgaria” (Kuklen, Bulgaria: Mitsubishi UFJ Research and Consulting, 2005).

Boyanov Boyan and Kehaiov Yanko, “Lead and Zinc Smelter (KCM AD), Bulgaria and Soil Contamination: Past, Present and Future,” in Sustainable Industrial Processing (Summit SIPS 2011): Volume 5, Environmental, Policy, Health, Legal, Management, Economical & Social Issues (Montreal: FLOGEN Star Outreach 2012).

Elke Beyer, Anke Hagemann, and Philipp Misselwitz, “Commodity Flows and Urban Spaces: An Introduction,” Articulo-Journal of Urban Research, no. 21 (2020).

Miroslav Pazdera, “The Shed-the Architecture of the A-Class Standard,” in Steel Cities: The Architecture of Logistics in Central and Eastern Europe, ed. Katerina Frejlachová, Tadeáš Říha, and Martin Špičák (Prague: Vi Per and PARK Books, 2020).

POLICY Links, “Emerging Trends in Global Manufacturing Industries,” University of Cambridge 12 (2013).

Aamna Mohdin, “The Fastest Shrinking Countries on Earth Are in Eastern Europe,” Quartz, January 24, 2018, ➝.

Jennifer Wolch, “Zoöpolis,” in Environment (Abingdon: Routledge, 2017), 275–301.

Kingdom of Bulgaria, General Directorate of Statistics, “General Results of the Census of the Population in the Kingdom of Bulgaria on December 31, 1910” (General Directorate of Statistics, Sofia).

New Silk Roads is a project by e-flux Architecture in collaboration with the Critical Media Lab at the Basel Academy of Art and Design FHNW and Noema Magazine (2024), and Aformal Academy with the support of Design Trust and Digital Earth (2020).